Personalization of consumer goods, sometimes referred to as mass customization, has been on the margins of the mainstream for several years. Often associated with footwear thanks to efforts like NikeID and Converse, the track record of offering the consumer personal discretion to choose certain product attributes is mixed. P&G ended their personalization initiative called Reflect.com after six years in 2005 and Adidas shut down their program earlier this year (following a first shutdown in 2005) only to subsequently relaunch it.

The business drivers seem clear enough. The customized product not only sells at a higher price and margin, but also delivers a strong customer experience and consumer intimacy.

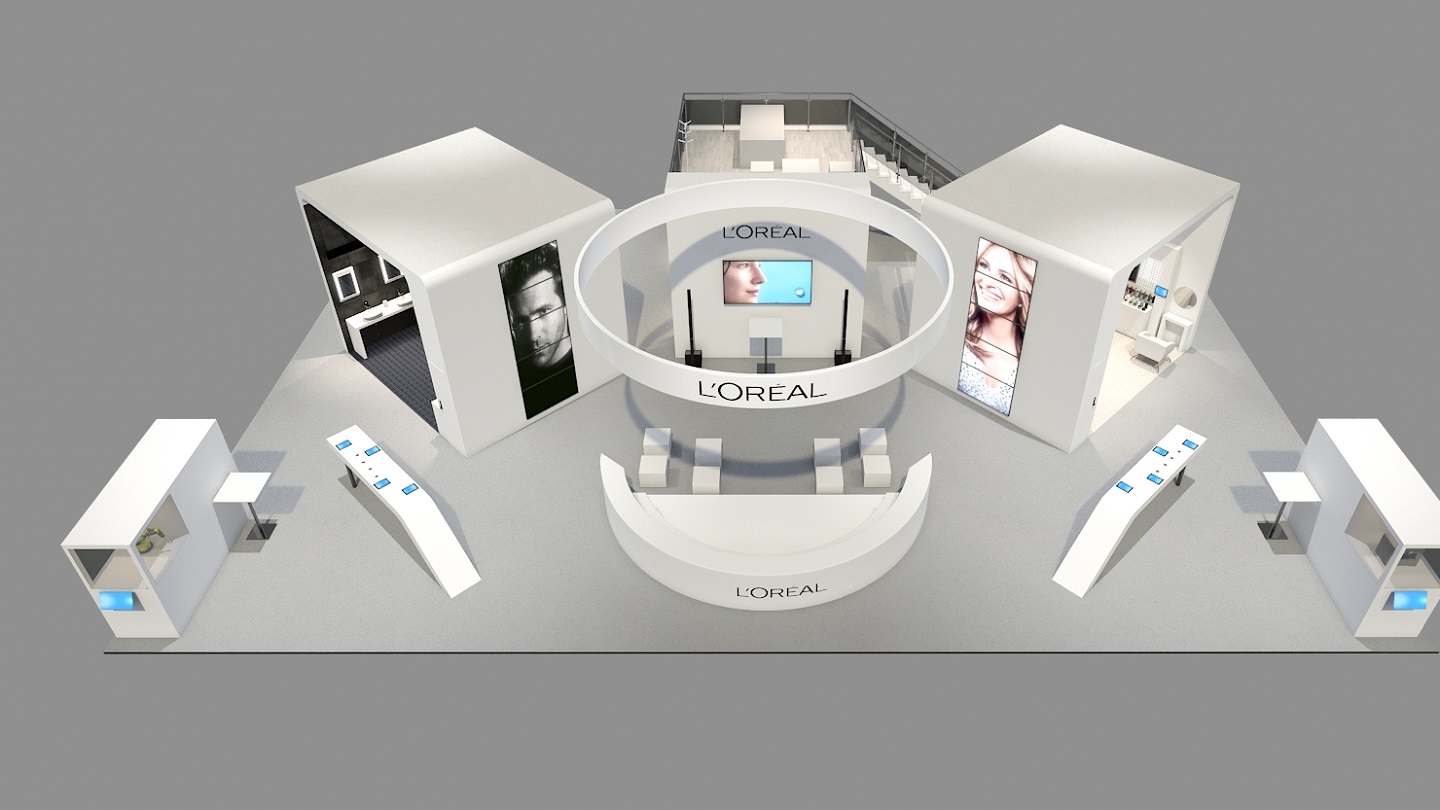

In 2019 personalization is one of the key consumer trends. A good example of this is L’Oréal, that unveiled in Paris this summer a concept called My Little Factory, which proposes to blend custom Lancôme foundations in 22,000 variations according to customer orders.

The “My Little Factory” initiative is a telling name and provides a useful lens through which to examine the potential impacts of personalization in operations.

Personalization starts with the customer

We spoke to Amir Andskog, e-Commerce Supply Chain Director at L’Oréal Luxe, to understand the challenges of initiatives like My Little Factory. He started by pointing out the need to rethink data management structures and then to consider reactivity.

“We certainly can’t create 22,000 new product codes and work as we did in the past. New, imaginative ways of tracking and storing products will be needed, ones that can manage master data in a much more flexible and adaptable way than today. The customer will expect lead times approaching those of the current standard products. Our factories must rethink their manufacturing processes in order to produce and ship within one day.” Amir Andskog, e-Commerce Supply Chain Director at L’Oréal Luxe

For a factory, this could mean redesigning not just scheduling cycles, but also other fundamental aspects, like quality processes, to be faster and leaner. Another likely implication is that the finished product will ship to the consumer directly from the factory. If manufacturing has been outsourced, as is the case for companies like Nike or adidas, the role of the supplier fundamentally changes too.

All of these challenges imply that a manufacturing mindset geared towards the customer is part of the personalization journey. Amir agreed, “Capabilities that bring the customer order deep into manufacturing processes will be critical to success.”

Challenging the manufacturing mindset

Increased customer proximity in the factory may also push for changes of other engrained mindsets. Manufacturing in many companies has undergone years of consolidation and massification. Fewer production centers and larger batches drove economies of scale in order to lower cost of goods. This approach extended to the sourcing of materials as well, all with an emphasis on removing production inefficiencies.

The result is often global manufacturing footprints, with large productions runs. For personalization to succeed at scale, this model must evolve. Most obviously, personalization means a run size of one. But with the customer proximity and lead time expectations of personalization global footprints may become more local again, or at the very least, regional.

“Personalization will oblige the organization to be mature enough to look at the total cost of the product including obsolescence, not just the manufacturing or sourcing cost. This new model will encourage shared profit and loss statements (P&Ls) across functions.” Eric Lefranc, an experienced operations expert with three different luxury companies

Eric echoed Amir’s thoughts about the challenge of customer proximity to manufacturing. “The data management and reactivity requirements will foster semi-automatic processes combined with empowered staff at the shop floor level that are highly motivated to be closer to the consumer.”

A boost for lean

Small runs, customer driven manufacturing and empowered staff are all hallmarks of Lean Manufacturing.

“Lean is a dynamic system that frames and stimulates the activities of employees aiming at flow improvement and people development. It enables employees to foster and leverage organizational learning in order to always better satisfy customers.” Florian Magnani, Operations professor and o-author of ‘540° to Lean’

Florian agreed that personalization could spur companies to embrace Lean in its purest sense, and indeed may be a necessary pre-requisite to success. He pointed out that even Toyota, whose production system inspired Lean, continue looking to shorten their production lines and give more responsibilities and autonomy to their staff in order to better respond to personalization.

Outlook for personalization

If Personalization is to truly succeed at scale, companies will have to rethink fundamental pillars of their manufacturing policy.

It goes deeper than technology. Indeed, it’s not apparent that L’Oréal’s My Little Factory will involve any Industry 4.0 elements. Total cost of ownership, quality processes, manufacturing footprint, supplier relationships, upstream/downstream silos, IT and data management are all elements that must be rethought in addition to channel placement. The result may be that what is old becomes new, and smaller, regional factories embrace Lean as a lever for commercial success through Personalization.

Ralf W. Seifert is Professor of Operations Management at IMD. He directs IMD’s new Digital Supply Chain Management program, which addresses both traditional supply chain strategy and implementation issues as well as digitalization trends and new technologies.

Richard Markoff is a supply chain researcher, consultant, coach and lecturer. He has worked in supply chain for L’Oréal for 22 years, in Canada, the US and France, spanning the entire value chain from manufacturing to customer collaboration.