- Dallara Automobili hired a new CEO to lead the company on an innovation journey, from its past of high-end car craftsmanship to its future as a digital firm.

- The company invested in creating two driving simulators powered by super-computers to improve time to market and reduce prototyping steps for its new designs.

- To push the limits of its engineering knowledge and drive innovation, Dallara entered its automobile chassis in the most competitive races, including Formula

- The new CEO changed the talent strategy: 98% of new hires are recent science and technology graduates.

There are only two places in the world that rival in importance as motorsport powerhouses: Motor Valley in northern Italy and Oxfordshire in England. Dallara Automobili is located near Parma, at the heart of Motor Valley – an economic cluster of 8,000 firms and 20,000 employees. Founded in 1972 by aerodynamics engineer Gian Paolo Dallara, the company specializes in manufacturing chassis for race cars. Its client list is a “who’s who” of motorsport: Maserati, Ferrari, Bugatti, Honda, Lancia, Renault and many others.

However, as the founder of Dallara reached retirement age, the company needed to find a new leader and a new strategy. With the exception of Formula 1, Dallara was already dominating its market. Where would it find new growth? Another challenge was unstable earning streams. The car racing industry moves in fast-paced cycles, driven by innovation and changes in racing regulations. This led to peaks and troughs in Dallara’s revenues. For its long-term survival, the company needed to smooth out its bottom line. More importantly, the challenge was to evolve from a high-end manufacturing company to a modern engineering and digital firm. The question was: How?

The broader issue

Automotive manufacturing – like all industries – is facing digital disruption. For automakers, the wake-up call has been the heated race to develop self-driving cars, with tech giants acting as trailblazers. In this context, maintaining a steady pace of technological innovation and manufacturing excellence is no longer enough for car companies to hang on to their leadership positions. Firms must also pursue digital breakthroughs. Traditional players need to avoid the trap of focusing solely on developing new digital products. Instead, they should aim to transform their entire company to compete on a new digital playing field.

Why is such an ambitious change necessary? Because the defining characteristic of digital business transformation is that it fosters organizational change through the use of digital technologies and innovative business models to improve corporate performance. Successfully implementing such a transformation entails a major renewal of business strategy and competitive dynamics, as well as structures, people and processes.

If you don’t use digital to reshape not just the business model but also the way you do your business – your processes inside – you will have a lot of problems.

Andrea Pontremoli, CEO of Dallara Automobili

Finding a new track

In 2007, the iconic 70-year-old founder of the firm, Gian Paolo Dallara, handed over the reins to a new CEO. Andrea Pontremoli was an unusual choice: He was the former head of IBM Italy, with 27 years of experience at the company in several countries. However, he had no experience in car racing or manufacturing. One of Pontremoli’s first dilemmas was whether to stick to the firm’s original vocation, which was to design and produce racing chassis known for their lightness and safety, or to push the company in new directions.

Coincidentally, also in 2007, the governing body of motorsport introduced new restrictions on racetrack testing in order to limit racing teams’ spiraling costs. This prompted F1 teams to invest in driving simulators. For Dallara, this led to a joint effort with Ferrari to develop a driving simulator that would give drivers the opportunity to practice while also allowing engineers to test new car components in a virtual setting. In fact, the simulator was a way to experiment with different handling set-ups on various racetracks and in varying weather conditions.

Building such a powerful simulator – capable of running complex mathematical experiments at high speed – proved to be much more difficult than planned. Only after several attempts by different engineering teams – first by car-race specialists and then by young IT graduates – did Dallara manage to develop a working simulator.

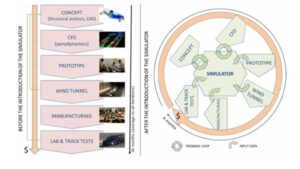

One of the main payoffs of the driving simulator was to shorten prototyping. Developing a new car previously took 36 months, on average. This included the concept stage, aerodynamics testing, prototyping, wind tunnel tests, manufacturing and, finally, product testing in the lab and on the racetrack. The process has been now reduced to nine months, with the simulator allowing Dallara’s engineers to create more feedback loops and iterations at all stages, including phases before a physical prototype is even built.

Another major avenue for change for CEO Andrea Pontremoli was to explore a new business model: engineering services. Dallara started providing simulation-testing services to its clients, leveraging its specialized knowledge in Computational Fluid Dynamics (CFD), a branch of aerodynamics that models the field of motion around a car. Dallara invested in the latest-generation processors to run complex CFD equations for both external clients and in-house projects. From a financial perspective, developing a consultancy model allowed Dallara to create a second revenue stream and stabilize its earnings. The company’s activities are now evenly balanced between manufacturing and services.

Did it work?

Dallara has undergone a fundamental shift: It is now primarily a knowledge-based company rather than a physical product manufacturer. The CEO’s new talent strategy reflects this shift: 98% of new hires are young, digitally savvy engineers, mathematicians and data scientists. Old processes and hierarchies have been replaced with a matrix organization that allows individuals to be assigned to projects on a need basis. As a result, knowledge is now widely shared across functional specializations and moves more fluidly within the firm.

Dallara is currently in a strong growth phase, with high market demand for its products and services. The firm has tripled the number of staff in recent years and now employs over 500 people. It has also built a second racing simulator in Indianapolis, a twin to its Italy-based simulator. In 2017, the company launched its first street-legal model, the Stradale, which consolidates Dallara’s racing expertise in a powerful “supercar.”

Takeaways

Dallara has not adopted new digital technologies just to jump on the bandwagon. It has transformed everything to become a digital player: its corporate strategy, business model and organizational structure, as well as employees’ skills and competencies. Manufacturing companies wishing to embark on their own business transformation journey can benefit from Dallara’s experience:

- Choose your clients wisely when you adopt a service-based model. In the words of CEO Andrea Pontremoli: “Don’t choose customers that will allow you to make a lot of profit. Rather choose customers that will allow you to learn.”

- Stay at the leading edge of innovation and technology by entering the toughest competition. Dallara decided to refocus on Formula 1 car racing, the most competitive of all motorsport categories. As a result, the firm’s engineers must constantly come up with novel solutions and push the boundaries of their knowledge.

- Be part of a business ecosystem. Dallara operates in the heart of Motor Valley. This allows it to reap the benefits of a “cluster economy model”: a dense network of niche manufacturers that offers specialized labor, capital, infrastructure and technology resources. “I believe you can’t have a competitive company if you don’t have a competitive territory,” says Pontremoli. “We have an incredible network to share things.”

- Leverage your data to create new customer value. Thanks to its new supercomputer-based simulator, Dallara started accumulating data and precise mathematical models of cars, components and race tracks. This data proved to be invaluable to original equipment manufacturers (OEMs) in becoming digital players. They hired Dallara to test components – in virtual form – under diverse road conditions and stresses. OEMs could thus test their concepts before building a physical prototype. For CEO Andrea Pontremoli, “the simulator makes it possible to drive a car that was never built. In fact, the pilot just drives a mathematical model and we learn a lot from that!”

THIS ARTICLE IS BASED ON IMD CASE: IMD-7-1803, AVAILABLE FROM THE CASE CENTRE AT WWW.THECASECENTRE.ORG.