Europe needs Chips Act 2.0 to compete in digital race

Former French finance minister Bruno Le Maire says Europe needs to act urgently to secure its supply of semiconductors or face relegation to the global slow lane. ...

Audio available

by Öykü Işık, Carlos Cordon Published October 17, 2024 in Technology • 7 min read

The recent explosions in Lebanon, triggered using tampered pagers and walkie-talkies, highlight a serious problem: how easily everyday electronics can be weaponized and how vulnerable global supply chains are to such threats.

This incident has put a spotlight on just how fragile these networks can be, raising urgent questions about what businesses need to do to protect themselves against similar risks in the future.

It’s a wake-up call for companies to rethink how they secure their supply chains and to address the new threats posed by the misuse of even the most common devices.

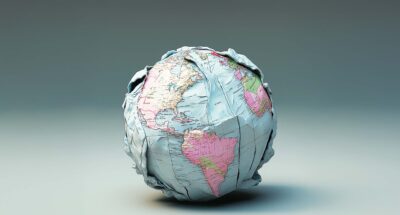

The incident underscores how easily electronic devices can be compromised and weaponized. In a globalized economy, supply chains are often complex and sprawling; electronic components may be designed in one country, manufactured in another, and assembled in yet another. In coffee supply chains there are, for instance, at least 10 steps from bean to cup.

With so many moving parts, supply chains have become easy targets for tampering and security breaches. Every new connection point is a potential weak spot.

Making things even harder, digitizing supply chains brings new risks. Hackers can tamper with sensors or hardware, leading to potential data breaches. With more digital elements in play, the chance for such attacks grows, adding another layer of complexity to supply chain security.

The 2020 SolarWinds hack showed this risk in action: attackers slipped malicious code into the company’s Orion software updates, compromising thousands of organizations, including Fortune 500 firms and US government agencies.

These risks blur the line between physical and digital threats, making the security landscape even more complicated. With more systems connected, it becomes easier for attackers to exploit weaknesses, letting them jump from a single compromised device to entire company networks.

This means businesses need to rethink their security strategies to keep up with these evolving dangers.

The lessons extend beyond the electronics industry. In the pharmaceutical world, keeping healthcare products secure is crucial, and the risks go beyond just physical tampering. From fake medications to issues with temperature-sensitive shipments like vaccines, any weak link in the chain can jeopardize entire batches.

These threats became clear during the COVID-19 pandemic when keeping vaccines at the right temperature was a major challenge. The Pfizer-BioNTech vaccine required storage at -70C, making transportation and storage a big hurdle.

In the automotive sector, meanwhile, where parts are sourced from all over and assembled under tight deadlines, even a small hiccup with a single supplier can throw off production, causing costly delays and hitting profits.

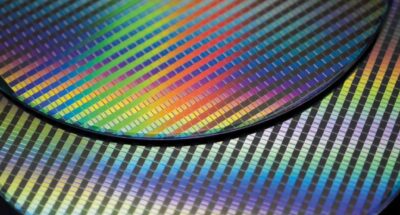

The global semiconductor shortage that hit in late 2020 crippled the auto industry, causing major production delays and billions in lost revenue.

Carmakers struggled to keep assembly lines running, showing how a single missing component can disrupt an entire supply chain.

The lesson from the devastating Lebanon incident applies here too: every handoff in the chain is a potential weak spot, making it crucial to secure each link to keep things running smoothly.

The more middlemen involved in a supply chain, however, the tougher it gets to keep things secure. Cutting out some of these steps or adding more transparency can help reduce risks, but it often means higher costs.

As a result, many companies are trying to take back control by shortening their supply chains. This sometimes means bringing production back home or looking to nearby regions, making them less dependent on far-off, unstable areas. It’s all about finding a balance between cost, control, and security.

“Many shoppers are now prioritizing sustainable and ethical products, even if it means paying a bit more.”

For companies, the pressure to manage these risks is huge. A cyberattack forced Toyota to shut down all its Japan factories for a day in 2022, resulting in a production loss of about 13,000 vehicles.

A serious breach in the supply chain can do more than just disrupt operations, though — it can damage safety and destroy a brand’s reputation. One high-profile incident could cause customers to lose trust, with long-lasting consequences. Protecting the supply chain isn’t just about solving tech issues anymore — it’s about business continuity.

With supply chain issues making headlines, companies are under pressure to prove their security is solid. If they mess up, they risk losing access to key markets and facing legal or financial hits.

Today, consumers and regulators are paying closer attention to how products are made and delivered. Many shoppers are now prioritizing sustainable and ethical products, even if it means paying a bit more. On the regulatory side, the EU’s Corporate Sustainability Reporting Directive forces companies to reveal their environmental and social impacts, including those throughout their entire supply chain.

This magnified pressure means that maintaining trust requires companies to be proactive. It’s not enough to react after the fact.

Dealing with these risks takes a mix of quick fixes and long-term planning. It’s crucial to get the physical security and cybersecurity teams working together, especially as digital tech gets more embedded in physical products.

This teaming up helps spot and fix weaknesses that might otherwise slip through the cracks. For instance, combining the know-how of logistics experts who handle sensitive goods with cybersecurity pros creates a stronger, more rounded strategy for managing risks. It’s about looking at both the physical and digital angles to cover all bases.

Proactive testing and monitoring also play a key role. Things like simulated attacks, and offering bug bounties can help spot vulnerabilities before real hackers find them.

Some companies even bring in ethical hackers to dig into their systems and find security gaps. These efforts help shift security from just reacting to problems to anticipating them, making it tougher for potential attackers to gain an edge.

Yet, even with all these efforts, it’s still tough for many companies to keep a clear view of their entire supply chain, especially beyond their first or second-tier suppliers. This is even harder when those suppliers are in politically unstable regions.

To cut down on these risks, some businesses are rethinking their reliance on cheaper production areas and are looking at moving production closer to home or to lower-risk areas. Shifting to regional hubs or local manufacturing offers better control and oversight, but it comes with a price — typically requiring big investments and infrastructure changes to make it work.

For instance: Apple supplier Foxconn pledged to invest a hefty $1.5bn to expand production in India, aiming to cut reliance on China and tackle geopolitical risks and supply chain disruptions.

It used to be all about cutting costs and increasing efficiency, but now the focus is on making sure products get where they need to go without any tampering.

Even with tighter security measures, the reality is that no system is ever fully secure. The key is shifting the focus to reducing potential damage and managing risks better.

This means thinking about security from the start — designing products with built-in protections instead of adding them in later. It’s also about teamwork: businesses need to join forces, set higher standards, and take responsibility together across the supply chain.

By doing this, they can set industry benchmarks, share knowledge about new threats, and respond quickly when problems arise. It’s all about staying ahead, together.

As we have seen, global supply chains can be fragile. Supply chain management used to be all about cutting costs and increasing efficiency, but now the focus is on making sure products get where they need to go without any tampering.

It’s a tough shift, but a crucial one for businesses that want to make it through the constant risks and challenges faced today. The real test is whether they can adjust quickly enough to turn their weak spots into strengths.

Professor of Digital Strategy and Cybersecurity at IMD

Öykü Işık is Professor of Digital Strategy and Cybersecurity at IMD, where she leads the Cybersecurity Risk and Strategy program and co-directs the Generative AI for Business Sprint. She is an expert on digital resilience and the ways in which disruptive technologies challenge our society and organizations. Named on the Thinkers50 Radar 2022 list of up-and-coming global thought leaders, she helps businesses to tackle cybersecurity, data privacy, and digital ethics challenges, and enables CEOs and other executives to understand these issues.

Professor of Strategy and Supply Chain Management

Carlos Cordon is a Professor of Strategy and Supply Chain Management. Professor Cordon’s areas of interest are digital value chains, supply and demand chain management, digital lean, and process management. At IMD, he is Director of the Strategies for Supply Chain Digitalization program.

July 10, 2025 • by Bruno Le Maire in Geopolitics

Former French finance minister Bruno Le Maire says Europe needs to act urgently to secure its supply of semiconductors or face relegation to the global slow lane. ...

Audio available

Audio available

July 8, 2025 • by Mike Rosenberg in Geopolitics

A new framework encourages leaders to see the world as PLUTO – polarized, liquid, unilateral, tense, and omnirelational. It’s time to think differently and embrace stakeholder capitalism....

Audio available

Audio available

July 7, 2025 • by Richard Baldwin in Geopolitics

The mid-year economic outlook: How to read the first two quarters of Trump...

July 1, 2025 • by Mridul Kumar in Geopolitics

Mridul Kumar, India’s ambassador to Switzerland, gives his personal view of his nation’s growing role as a leader in a multipolar world....

Audio available

Audio availableExplore first person business intelligence from top minds curated for a global executive audience